| Number of turbines | Turbine capacity | Blade length | Tower height |

|---|---|---|---|

| 55 | 0.66 MW | 23.5m | 50m |

The second stage of the Tararua wind farm project was a huge success – commissioned in 2004, this brought the total number of operating turbines to 103 with a total installed capacity of 67MW.

Blackley Construction assisted the project through trenching and installing all the required cabling onsite. Combined with the Stage 1 installation, this wind farm was supplying 32,000 Kiwi homes with their daily energy requirements – we’re happy that we could help!

Even today, the project has been claimed to continue at the best possible capacity – nearly 20-years later!

The fact that the wind farm is operating as well as it was 20-years ago instils us with pride. We follow a three-part process to ensure this:

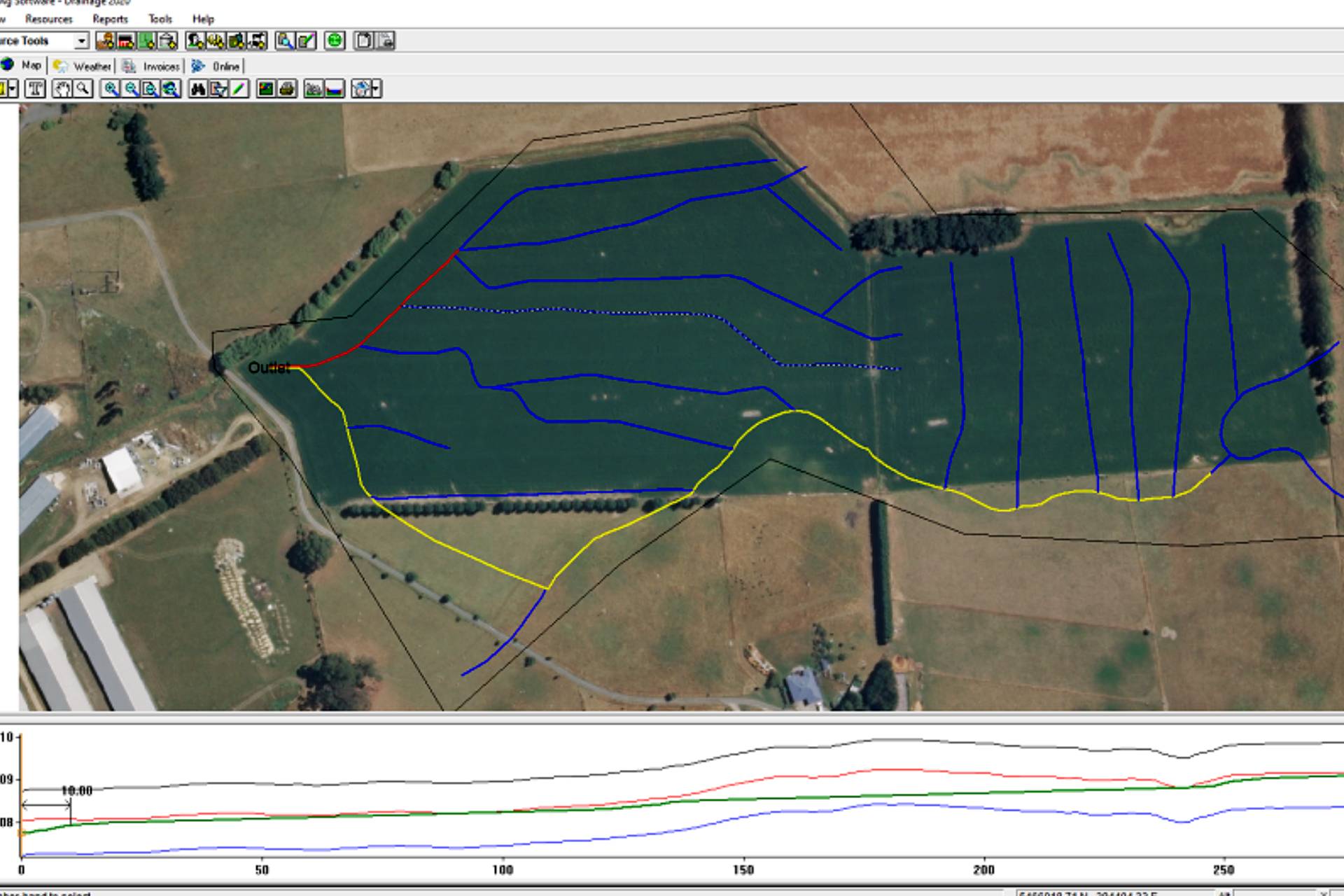

- We excavate an accurate and consistent trench with GPS technology

- We control the amount of bedding material placed and handle cabling as little as possible, reducing the risks associated with cable handling

This is important as not only is it benefiting the wind farm owner and the longevity of the wind farms, but also it serves the everyday Kiwi household that relies on the energy from the wind farm.

We’re glad to have helped Kiwi homes thrive over the past 20-years and are excited to be a part of a greener move towards energy production.